Namuhla, ake sihlele indlela ehlelekile yezinqubo zokusebenza zokuphepha zomshini we-cryogenic deflashing. Ngenkathi sesivele sinokuqonda okujwayelekile kokusebenza komshini ngokubuka amavidiyo wokufundisa, kubalulekile ukulungiselela umkhawulo womkhiqizo unqume kahle. Imihlahlandlela yezokuphepha yokusebenzisa umshini. Lokhu kuzosenza sikwazi ukwenza kahle umsebenzi wokunquma onqenqemeni.

- Njengomshini wefriji womshini we-cryogenic deflashing, ukulethwa kwe-nitrogen ewuketshezi kubalulekile. Ngaphambi kokuqala, qala ngokuvula i-liquid nitrogen valve enkulu. Uyacelwa ukuthi uqaphele ukuthi umfutho wokuhlinzeka we-nitrogen we-liquid kufanele ube phakathi kuka-0.5 ~ 0.7MPA. Ingcindezi ephakeme ngokweqile ye-nitrogen ewuketshezi izolimaza i-liquid nitrogen solenoid valve.

- Jikelezisa i-othomathikhi-ngesandla switch to [Manual] isikhundla.

- Cindezela inkinobho yokuqalisa amandla okusebenza, ngalesi sikhathi ukukhanya kwamandla okukhanya kwamandla azokhanyisa.

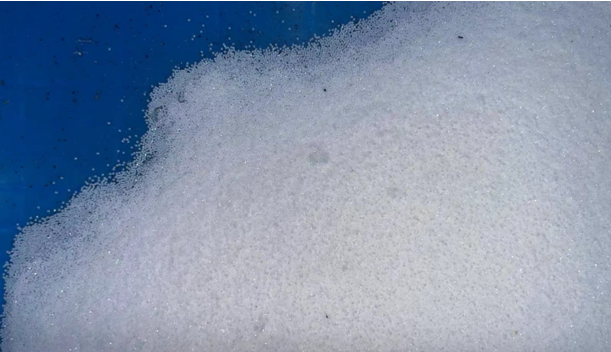

- Vula umnyango wegumbi lokusebenzela, futhi ngemuva kokubeka ama-pellets omisiwe emishini, vala umnyango. Cindezela inkinobho ye-Ejector ukuze uqale ukujikeleza kwesondo le-ejector, bese ulungisa isilawuli se-ejector wheel Speed.

- Cindezela inkinobho yokudlidliza isikrini ukuqala ukusebenza kwesikrini esivuthayo. Lapho isikrini sokudlidliza sisebenza, ama-pellets azosakazwa adutshulwe emazingeni okushisa asekamelweni.

- Gcina isimo esingenhla bese uqhubeka nokusebenza imizuzu engama-45. Qinisekisa ukusakazwa okujwayelekile kwama-pellets ngokubuka umgodi wokubheka egumbini lokuphamba egumbini le-pellet kanye nomsindo wama-pellets ukushaya umshini. Ngemuva kokuthi umsebenzi usuqediwe, cindezela inkinobho yokudlidliza isikrini ukumisa isikrini sokudlidliza ngaphambi kokucindezela inkinobho yesondo le-ejector ukumisa ukujikeleza isondo le-ejector.

- Lapho ukukhanya kwe-Power Inkomba kuvuliwe, sicela uqaphele ukuthi ungasebenzisi isandla sakho lapho uvula noma uvala umnyango wegumbi lokusebenza. Qinisekisa ukuthi umnyango wokusebenza uvaliwe. Qiniseka ukuthi uyeka isikrini esidlidliza ngaphambi kokumisa isondo le-ejector.

Qaphela:Uma ama-pellets egcinwe egumbini le-pellet, kungahle kube nenkinga ngokuhamba okubushelelezi kwama-pellets lapho imishini iqalwa kabusha. Ukuqinisekisa ukuthi imishini ingathola ngokushesha amabutho aphumelelayo lapho isebenza futhi isebenza futhi, sicela ugcine ama-pellets agcinwe esikrinini esidlikizayo lapho imishini isesimweni esimisiwe.

Indlela Yokuphendula:Misa isikrini sokudlidliza ngaphambi kokumisa isondo le-ejector. Shintsha i-othomathikhi-Manual Shintshela esimweni esizenzakalelayo.

Lapho usetha isilawuli sokushisa kanye nesikhathi esivelayo, kuyadingeka ukubheka amazinga okushisa womkhiqizo ngaleso sikhathi futhi wengeze isikhathi esifanele sokuqamba imizuzu emi-2 kuya kwayi-3. Sebenzisa isilawuli sejubane le-Ejection Speed ukusetha Izimo zokucubungula ezidingekayo ukuze imikhiqizo icutshungulwe

Isikhathi sePosi: Nov-07-2023