I-Ultra Shot Cryogenic Deflashing/Deburring Machine (Umshini Wokufiphalisa I-Cryogenic Owenziwe e-Japan)

Isibonisi Esinemininingwane

Umshini Wokufiphalisa I-Cryogenic WaseJapane

Izinketho eziyinhloko zengxenye yomshini we-Cryogenic deflashing

I-Janpanese Yenziwe Umshini Wokuqaphalisa I-Cryogenic

Isingeniso Somkhiqizo

● Wonke umshini ungowoqobo wenziwe/ungeniswe usuka e-Japan.

● I-STMC inikeza insizakalo yokuthengisa kwangaphambili kanye nangemuva kokuthengisa ilandela izindinganiso nezimfuneko ze-RESONAC Group.

Isixhumi esibonakalayo seSoftware

Isikrini Sasekhaya

Isikrini Esiyinhloko Esisebenzayo

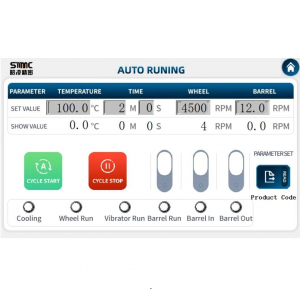

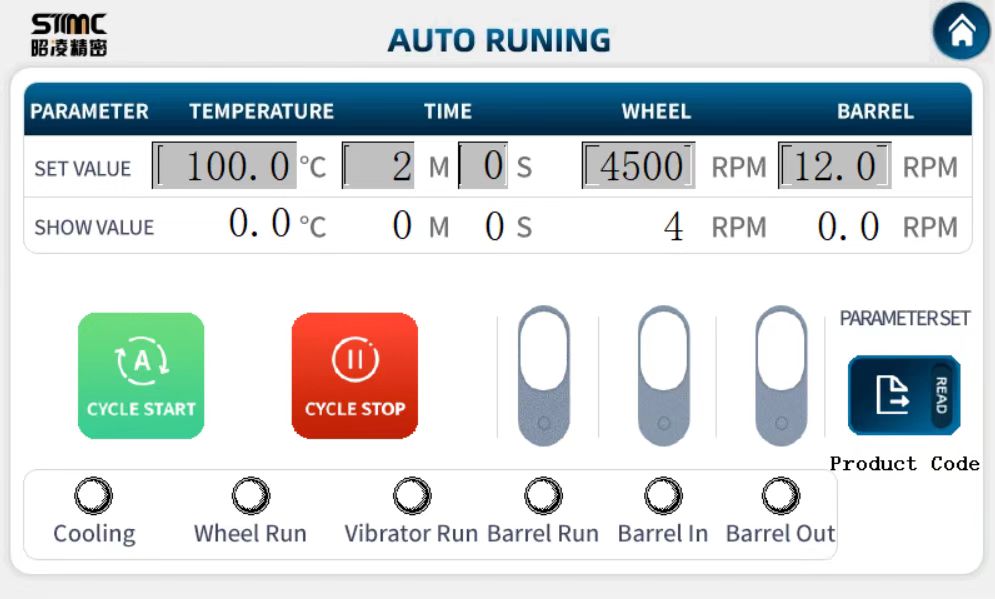

Imodi ezenzakalelayo

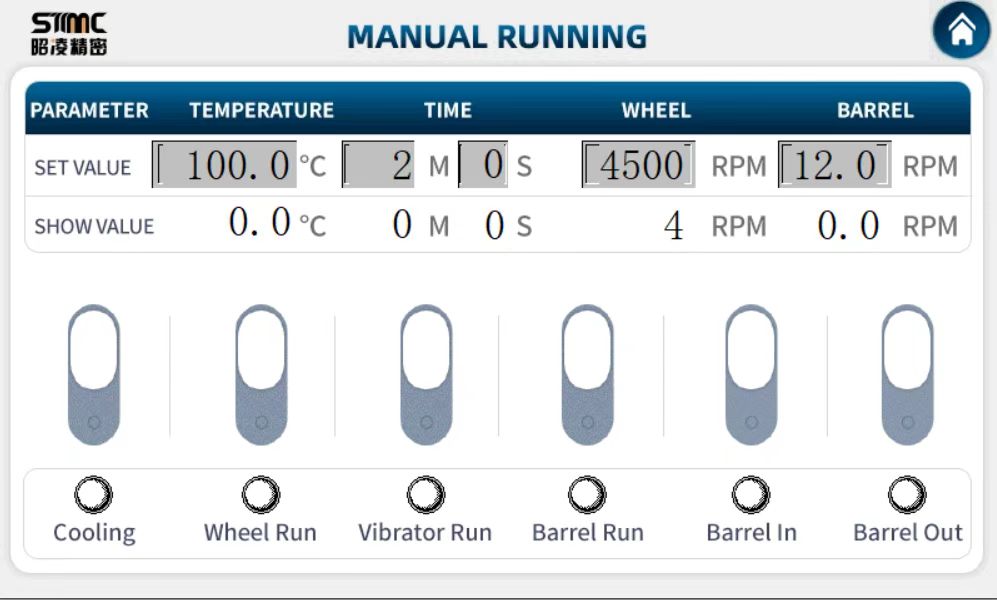

Imodi Yokusebenza Mathupha

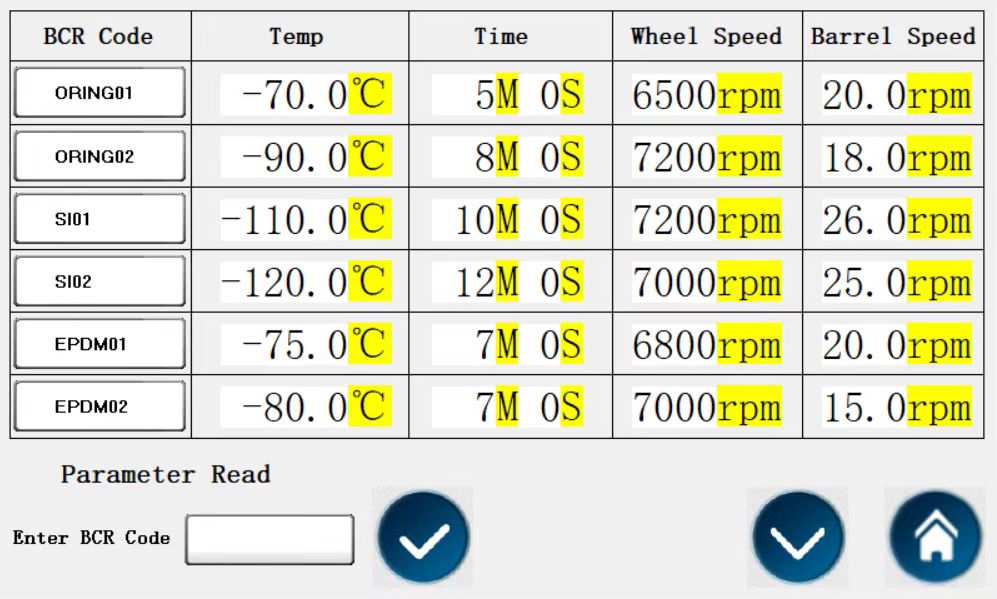

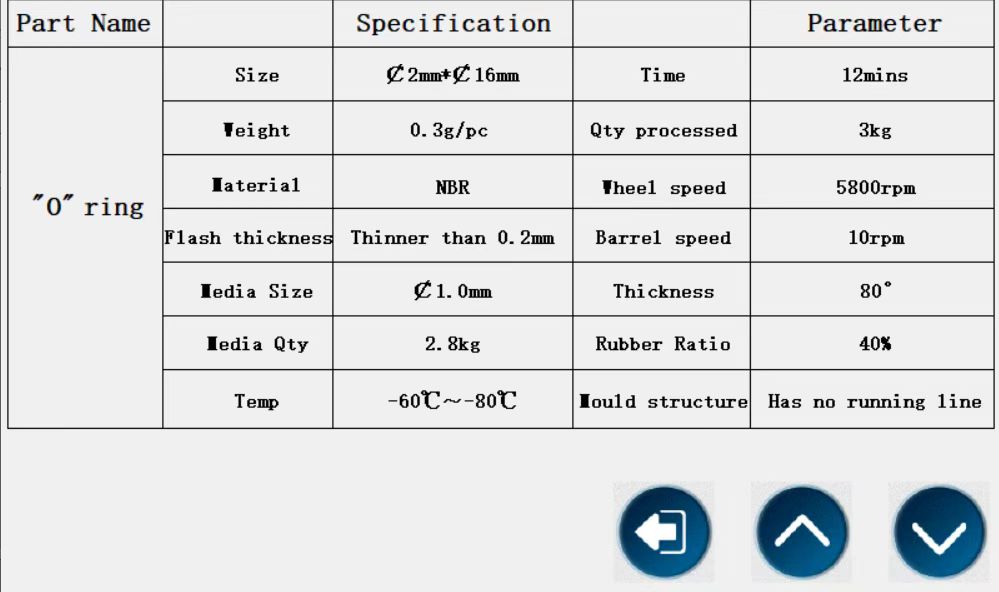

Ipharamitha Gcina / Funda

I-Parameter Library

I-Man-Machine Interaction & Control Systems

1. Kulula ukusebenzisa isixhumi esibonakalayo sokusebenza kwesikrini esithintwayo esinosayizi omkhulu, okuhlanganisa ukwesekwa kwezilimi eziningi kanye nekhibhodi ye-QWERTY, okwenza ukukhiqizwa kusheshe futhi kuhambisane.

2. "Ukuthinta okukodwa ukuqalisa", vumela ukugcinwa kwepharamitha enkulu nokufunda, kulula futhi kulula ukuyiphatha.

3. Ngazo zombili imodi yokusebenza eyenziwa ngesandla kanye ne-othomathikhi, okuhlanganisa ukuhlola okujwayelekile kokulungisa, ukuvikelwa kwephasiwedi, uhlu lokucubungula kanye nokuxilongwa kwesikrini.

4. Uhlelo lokulawula oluzenzakalelayo kanye nesixhumi esibonakalayo somshini singenziwa ngokwezifiso ngokuvumelana nezidingo zamakhasimende kanye nokusebenzisa imikhuba.

5. Ukuqapha kwepulatifomu yamafu kuyatholakala, vumela ukuqapha kwesikhathi sangempela nokuhlaziya ukusetshenziswa nesimo sokusebenza komshini.

Intelligent Manufacturing

Ukuze kuhlangatshezwane nezidingo zokusebenza zedijithali, ulwazi kanye nobuhlakani, i-STMC iyakwazi ukuhlinzeka ngokuthuthukiswa kwemishini.

1. Setha imvume yokusebenza ukuze ugweme izingozi ezibangelwa izisebenzi ezingagunyaziwe eziqhuba umshini.

2. Finyelela futhi uthole amapharamitha afakwe ngaphambili ohlelweni ngokuskena ibhakhodi.futhi uvumelanise irekhodi lepharamitha yokucubungula kukho kokubili uhlelo lokulawula izimboni kanye nomshini.

3. Isistimu yomshini inomhlahlandlela wokusebenza owakhelwe ngaphakathi kanye nendlela yesisombululo sokungasebenzi kahle, engasiza opharetha ukuthi bathole inkinga ngokushesha ngolwazi oluyingcaca futhi barekhode ngokuzenzakalelayo ukuloga okuhlulekayo.Ngesikhathi esifanayo, isikrini sizobonisa imininingwane yokuxhumana yomkhiqizi (i-STMC) yesevisi.

Qaphela: Ngokwesisekelo salolu hlelo lokulawula izimboni, isofthiwe ngokwayo ingenziwa ngokwezifiso futhi ithuthukiswe (le ngxenye ayifakiwe kwikhotheshini), ukuze kuvunyelwe ukwabelana ngedatha phakathi kwezinto zokusebenza kanye nesistimu yebhakhodi yeklayenti/isistimu ye-MES, ngakho-ke ukubona ukufinyelela kwemishini ohlelweni lwe-MES nezinto zokusebenza (ukukhiqiza) emafini.